Siemens PLM Software has hosted a few events recently in the virtual world of Second Life that have been fun and interesting for anyone interested in CAD. And according to their calendar, this is just the beginning. During one of these events, held on May 20, the company hosted a live launch of its Velocity series in Boston while at the same time hosting a live virtual launch in Second Life. Although I would never have been able to attend the Boston event, I was able to find my way into the Second Life event. What a great presentation!

Photo of Bruce Boes in Second Life and in real life giving a presentation about Siemens PLM Software Velocity Series

By attending in Second Life, I was able to find out the following information presented by Bruce Boes, global vice president, Velocity Series Marketing:

The company has 425 channel partners on a global basis

90% of the company’s Velocity business goes through their channel partners

Siemens PLM Software currently has a third of the market and is projected to represent half by 2011

A case study on Conn-Weld Industries showed a reduction in design time of 66% in their move from 2D to 3D

The presentation was fun and energetic and really nothing like I would have expected or had ever seen before having worked in the engineering field for the last 25 years or so. Lets face it, engineers aren’t usually thought of as the life of the party. But Siemens PLM Software showed me that maybe things are changing a little in our field. Throughout the presentation, a guy who introduced himself as the “answer man” would jump onto the stage to offer his own take on what was going on. The distraction provided a unique method of introducing key points.

A photo of the Answer Man who kept interrupting the Siemens PLM Software Velocity Launch Event in Boston.

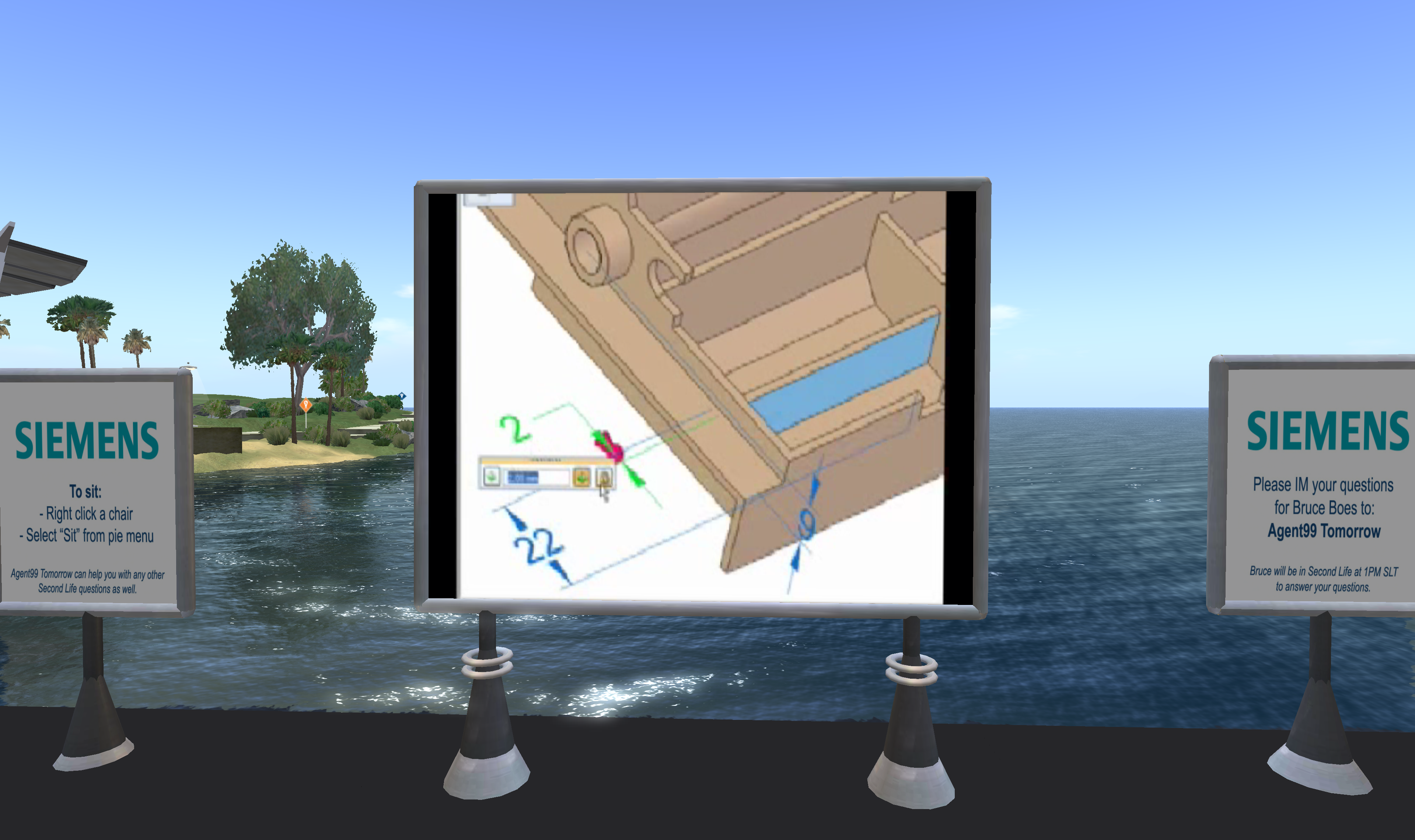

Several videos were shown to demonstrate the ease with which products can be designed with the software in the Velocity series. I have to admit that I primarily use CAD for mapping and producing civil engineering plans which are quite a bit different from mechanical drawings. But even I could appreciate the ease with which products could be designed and then changed on the fly.

Some benefits included the ability to create specific constraints in the drawing such as holding a particular dimension, and then making changes to the product without having to worry about going back and checking or updating each constraint. During the editing process, the software revised everything on the fly as specified. You can even tell the software to always make sure a particular hole or component is always located in the center of another part – thus specifying a constraint based on a formula. That seemed impressive to me. I wish I could do that in my CAD software with my roadway or sewer design as easily as this was done in the Siemens PLM Software.

So in answer to why this type of drawing manipulation – termed “synchronous technology” is useful, Boes said it will allow the engineer the freedom to be an engineer and not have to be fully proficient in CAD. And this is good – if engineers can actually start creating the product drawing while they are designing, a significant decrease in time and elimination of mistakes can be realized. And this is what company’s are experiencing. Boes went through several design process examples to show how much time and money can be saved.

Anyway the grand finale was a man who got on stage and put himself inside a balloon. Now there’s something you don’t get to see everyday. And that part happened at the real life event!